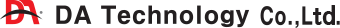

Press Notching M/C (Roll to Roll)

-

Description

Automated equipment for notching of positive and negative electrode material to create individual electrode layers with tab profile. Process includes unwinding the electrode material, notching the material with punch press and rewinding back with protective film.

-

Features

- Mold Press Mechanical Notching

- Electrode Meandering Prevention & Automatic edge position control

- Ultra Precision Feeding System

- Vision Inspection of Notched Electrode Dimension

- Scrap & Foreign Particle Collection

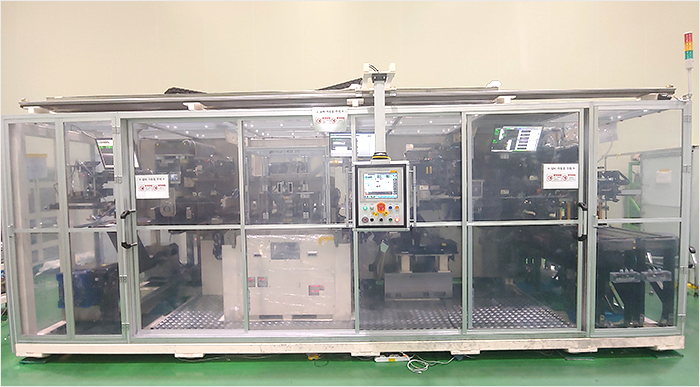

Laser Notching M/C (Roll to Roll)

-

Description

Automated equipment for notching of positive and negative electrode material to create individual electrode layers with tab profile. Process includes unwinding the electrode material, laser notching the material and rewinding back with protective film.

-

Features

- Laser Optical Notching

- Automatic electrode edge position control

- High-speed Feeding System

- Vision Inspection of Notched Electrode Dimension

- Scrap & Foreign Particle Collection

- Automatic Reel Change

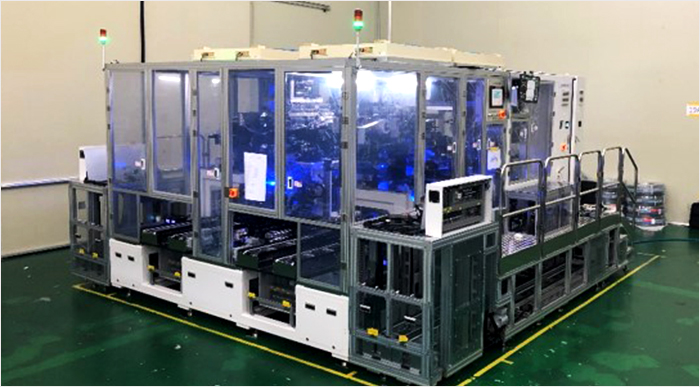

Notching & Cutting M/C

-

Description

Automated equipment for notching of positive and negative electrode material to create individual electrode layers with tab profile. Process includes unwinding the electrode material, notching the material with punch press and stacking the layers in magazine.

-

Features

- Mold Press Mechanical Notching Applicable

- Electrode Meandering Prevention & Automatic edge position control

- Vision Inspection of Notched Electrode Dimensions (In-house program)

- Scrap & Foreign Particle Collection

- Automatic Reel & Magazine Change

Reel Cut Stacking M/C

-

Description

Automatic equipment for stacking of electrodes together with separator to form a Cell. The process includes unwinding of the notched electrode roll, side cutting and aligning the electrode based on the vision inspection and stacking with continuous separator in a zig-zag pattern.

-

Features

- Vision Inspection for electrode aligning and defect detection (In-house program)

- Automatic electrode edge position and tension control

- Input and Production Lot ID Management

- Scrap & Foreign Particle Collection

Magazine Stacking M/C

-

Description

Automatic equipment for stacking of electrodes together with separator. The process includes inputting the magazine with notched and cut electrodes, aligning electrodes based on the vision inspection, and stacking the layers of electrodes with separator to form a folding cell.

-

Features

- Vision Inspection for electrode aligning and defect detection

- Automatic electrode edge position control

- Input and Production Lot ID Management

- Scrap & Foreign Particle Collection

- Magazine Automatic Change

Laminating

-

Description

Equipment for making bi-cell by piling up positive and negative electrodes and separator in sequence with high accuracy. The process includes heat pressing of notched electrodes and separator, inspection, and unloading of the laminated cells into the magazine.

-

Features

- Electrode and Separator Meander Adjustment

- High-speed real-time Position Calculation & Correction Align System(In-house Program)

- High-speed Precise Side Cutting

- Electrode & Separator Lot ID Management

- Processed bi-cell Inspection

- Automatic Magazine Change

Folding

-

Description

A process equipment that arranges and supplies bi-cells by type and seals the cells after laminating and winding bi-cells in separator.

-

Features

- Preventing 2-sheet Issue

- Preventing Electrode and Separator Meandering

- High-speed real-time Position Calculation & Correction Align System(In-house Program)

- Gap Data Management Between Cells

- Short Check & Thickness Management

Packaging Loader/Unloader

-

Description

Equipment to automate cell input and discharge during process change. (cell to tray or tray to cell)

-

Features

- Tray-based process

- Interlocked with main facility

- Cell gauging to prevent tab damage

Wing Folding

-

Description

Pouch cell’s edge(wing) folding equipment after degassing.

-

Features

- Heating Press & Cooling Press Unit

- Pick & Place Robot

- Link to the Upper Scheduler

- 3D Product Folding System Applicable

Packing M/C

-

Description

Equipment for loading faultless cells onto the tray before final shipment

-

Features

- Cell position correction stage

- Tray automatic discharge after palletizing

TOP

TOP